ActiveU

ActiveU is a family of activated carbon manufactured from natural sources.

ActiveU is available in variety of grades and in powdered, granulated and pelleted forms.

It is ideal for several applications such as liquid and vapor phase removal of organic compounds.

We also offer products for medical (blood cleansing, protein adsorption, and enterosorbents) food storage application. In addition, we offer impregnated activated carbon for use in catalysis related applications.

We supply small to large quantities of activated carbon. We are ready to ship your order for 1 kg, 25 kg, 100 kg, and larger containers.

FAQ

Activated carbon is referred to porous carbon that is produced through a prosity-development process called activation. The activation process involves high temperature treating of already pyrolyzed carbon (often referred as char) using activating agents such as carbon dioxide, steam, potassium hydroxide, etc. Activated carbon has great adsorption capabilities which is why it is used in liquid or vapor phase filtration media. Activated carbon has surface area greater than 1,000 square meters per gram.

Adsorption is the process by which liquid or gaseous molecules gets attracted to the inner pore walls of activated carbon. Adsorption is different from absorption. In absorption, molecules are taken up by the volume, not by the surface (as in adsorption).

The use of activated carbon extends back into history. Indians used charcoal for drinking water filtration, and carbonized wood was used as a medical adsorbent by the Egyptians as early as 1500 B.C. Activated carbon was first manufactured industrially in the first part of the twentieth century, when it was used in sugar refining. Powdered activated carbon was first produced commercially in Europe in the early 19th century, using wood as a raw material.

In general, activated carbon can be produced from a variety of carbonaceous material. The three most common raw materials for activated carbon are wood, coal and coconut shell.

Activated carbon made from wood is called activated charcoal.

Decolorization of sugar and sweeteners, drinking water treatment, gold recovery, production of pharmaceuticals and fine chemicals, catalytic processes, off gas treatment of waste incinerators, automotive vapor filters, and color/odor correction in wines and fruit juices.

As per IUPAC standards, pores are usually categorized as follows:

Micropores: referred to pores less than 2 nm; Mesopores: referred to pores between 2 and 50 nm; Macropores: referred to pores greater than 50 nm

Coconut shell activated carbon has a large quantity of micropores making it superior to coal grades for the removal of smaller organic compounds, low boiling point chemicals with strong odors and dechlorination applications. Coconut shell activated carbon is a material of choice for manufacturers of water filters and respirators.

Coal based and wood based carbons contain meso and macropores and thus are used in applications such as dye removal where larger color compounds can be successfully adsorbed.

Iodine number is a commonly used parameter used to characterize activated carbon performance. It is a measure of activity level (higher number indicates higher degree of activation), often reported in mg/g.

It is a measure of the activated carbon’s resistance to attrition. It is an important indicator of activated carbons ability to maintain its physical integrity and withstand frictional forces imposed by backwashing, etc. We follow ASTM standard 3802 to determine hardness number.

CTC is most widely used method is to measure the carbons capacity to adsorb carbon tetrachloride and express this as a weight/weight %. This is determined by flowing CTC laden air through a sample of carbon of known weight, under standard conditions, until constant weight is achieved. The weight of CTC adsorbed is referred to as the carbons % CTC activity. We follow ASTM standard 3467 to CTC activity.

The internal surface area of a carbon is usually determined by the BET (Brunauer, Emmett and Teller) method.

1 kg.

Please call us at +380442332443 or email us at sales@carbon.org.ua.

Please call us at +380442332443 or email us at sales@carbon.org.ua.

We can help you determine the best grade of activated carbon for your application. Please call +380442332443 or email us at sales@carbon.org.ua.

We sell many different grades of activated carbon from different raw materials, available in both granular, powder and pellet form. We provide technical consultation, competitive pricing, and can develop custom based activated carbon. No order is small for us. We supply activated carbon as low as 1 kg.

Yes. Some of our products are certified to ANSI/NSF Standard 61. Additionally, others meet all requirements of AWWA, Chemical Codex, and ASTM protocols.

On request, we can provide the price for larger quantity orders. Please call us at +380442332443 or email us at sales@carbon.org.ua.

Request Bulk Quote

Carbon-Ukraine offers competitive pricing from one pallet to mixed truckloads of virgin coconut shell activated carbon. We offer NSF certified activated coconut carbons from minus 325 mesh to 4 mm pellets. We can also supply carbon tetrachloride (CTC) 70 if required.

|

PRICING FOR CTC 60, IODINE 1150 MG/G, (10/1/2012 – 1/1/2013) |

|||||

|

Minimum order |

Cost/ton |

Packaging size |

Carbon type |

Mesh size |

Iodine number |

|

1 MT* |

$2300 |

500 kg or 25 kg bags |

Virgin coconut shell activated carbon |

8 x 30, 12 X 40 |

1,150 mg/g |

|

5 MT* |

$2200 |

500 kg or 25 kg bags |

Virgin coconut shell activated carbon |

8 x 30, 12 X 40 |

1,150 mg/g |

|

10 MT** |

$2100 |

500 kg or 25 kg bags |

Virgin coconut shell activated carbon |

8 x 30, 12 X 40 |

1,150 mg/g |

|

20MT** |

$2000 |

500 kg or 25 kg bags |

Virgin coconut shell activated carbon |

8 x 30, 12 X 40 |

1,150 mg/g |

|

*Shipping not included **Price is CIF US Port |

|||||

Reactivated carbon

Reactivated carbon is spent carbon that is recycled by treating it at elevated temperature in oxidizing atmosphere.

Reactivated carbon can be used in place of new virgin carbon for aqueous and vapor applications to remove organics. Reactivation process destroys organic compounds that had been adsorbed onto the carbon and thereby increases the surface area and pore volume of the spent carbon.

Reactivated carbons can be used in all applications where virgin carbons have been traditionally used and are suitable for use in treatment of potable water, process water, wastewater, groundwater remediation and other applications.

We offer several grades of coal, wood and coconut shell based reactivated carbon depending on mesh sizes and iodine number:

|

|

|

VOC removal

The use of activated carbon is one of the leading technologies for the removal of volatile organic compounds (VOC’s) from commercial and industrial air discharges. ActiveU can be used for the capture of VOC’s in many industries. These include, but not limited to, petrochemical, pharmaceutical, metal processing, pulp and paper, and food processing. Further downstream applications include dry cleaning, paint spray booths, plating, HVAC (heating, ventilation, and air conditioning) systems, solvent recovery systems, groundwater remediation, and indoor home air purification units.

There are no articles in this category. If subcategories display on this page, they may contain articles.

Carbon Molecular Sieves for Pressure Swing Adsorption (PSA)

We offer special coal grades of carbon molecular sieves optimized for pressure swing adsorption (PSA). Our carbons can be used in a variety of gas separations including separating nitrogen and carbon dioxide from the air, separating methane from ferment gas, and separating hydrogen from blast furnace exhaust or from the methyl alcohol gas. We also supply large quantities of carbon molecular sieves for PSA.

Heavy metal recovery

Use of activated carbon use for gold and other heavy metal recovery has been increasing for the past 3 decades. Our gold recovery activated carbon consists of highly uniform granules and is specifically designed for use in precious metal recovery circuits. Our granular coconut shell activated carbons have the right pore sizes for use in carbon-in-leach (CIL), carbon-in-pulp (CIP) and carbon-in-column (CIC) applications. The available mesh sizes for gold recovery activated carbon are 6×12 and 8×16. We can provide additional mesh sizes based on specific needs. We also supply activated carbon for silver recovery.

Decolorization

ActiveU offers decolorization grade activated carbon specifically designed to efficiently purify and/or decolorize many aqueous and organic liquids.Decolorization grade is made from wood and is available in two grades: washed and unwashed.

Our carbons have found wide acceptance in the chemical and food process industries for the decolorization and purification of numerous aqueous and organic liquids. Some of these are the purification of glycols, soda ash and caustic liquors, sugar/sucrose solutions, pharmaceuticals, and plasticizers.

If you need larger quantities of material or want to use ActiveU for specific liquids then please email your quote request at sales@carbon.org.ua.

Alcohol purification

Activated carbon has been used for adsorbing many different chemical compounds originated from the manufacturing process including those that cause unwanted flavours spirit from alcohol.

The selection of activated carbon for alcohol purification depends on the concentrations and molecular weight of the compounds tha needs to be adsorbed.

Self Propagating High Temperature Syntheis Reactor – SHS Reactor, customized equipment manufacturing

Our Ukrainian partner Materials Research Centre (MRC) offers manufacturing of SHS Reactor.

Our partners from MRC (Kiev, Ukraine) design and manufacture customized laboratory reactors for Self-Propagating High-Temperature Synthesis

Self-Propagating High-Temperature Synthesis (SHS), also known as combustion or autoignition synthesis, creates materials by starting an exothermic reaction among powdered reactants. It stands out for being self-sustaining—generated heat continues the synthesis without needing an external heat source. SHS is widely used in making various materials like ceramics, intermetallic compounds, and composites.

The design of a reactor for Self-Propagating High-Temperature Synthesis (SHS) is a critical aspect of ensuring the success and safety of the process. The reactor must be able to initiate and sustain the exothermic reaction while allowing for control over key parameters.

We provide development of SHS technologies, design and manufacturing of customized specialized equipment intended for synthesis of novel materials using non-critical raw materials as a precursor for SHS technology.

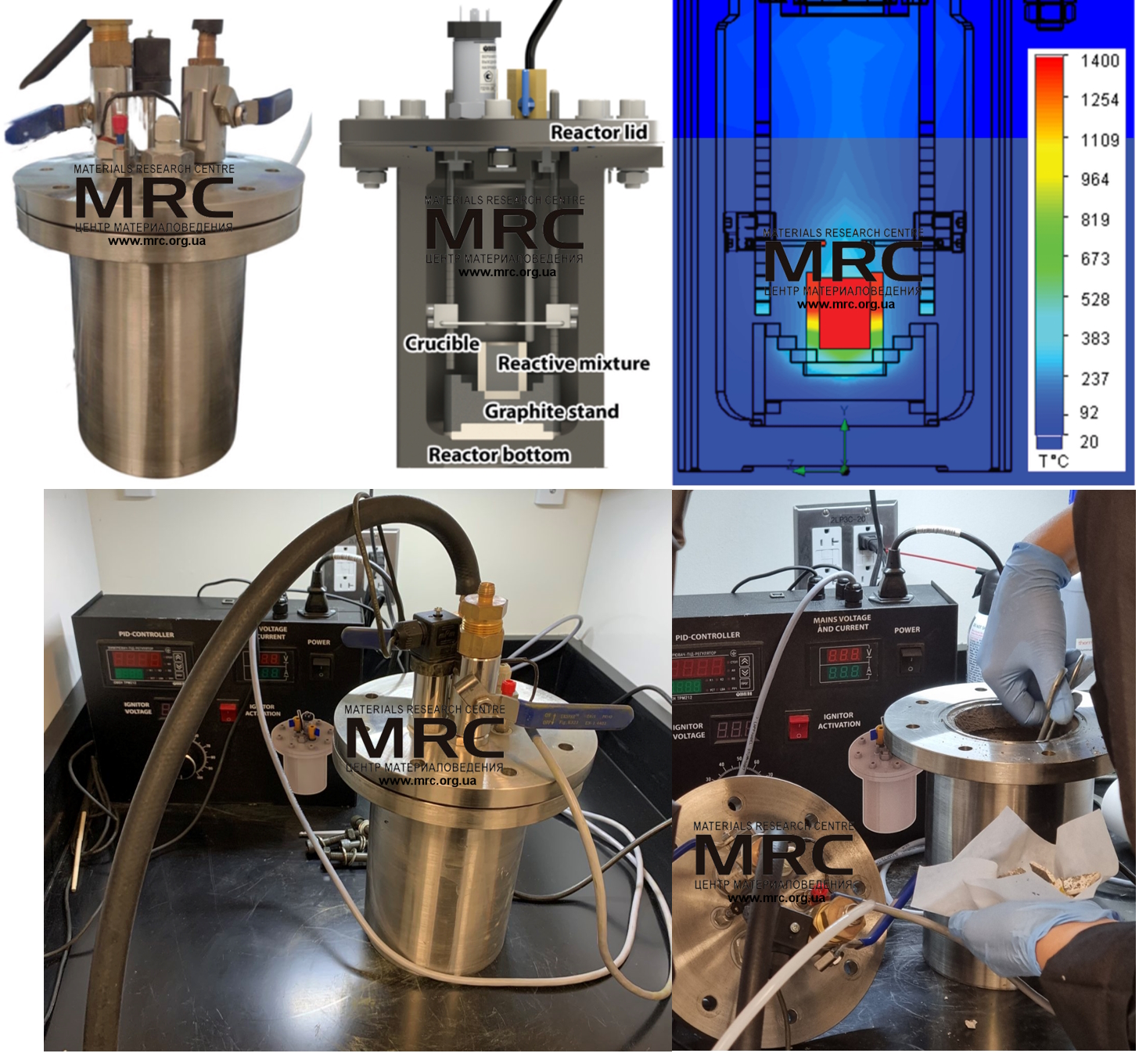

SHS reactor and its thermal model: General view of the SHS reactor; Cross-section of the reactor; Thermal model of the SHS reactor with 60 g of the reaction mixture showing the temperature field in the reactor during the combustion synthesis.

Vorotilo, S., Shuck, C.E., Anayee, M. et al. Affordable combustion synthesis of V2AlC precursor for V2CTx MXene. Graphene and 2D mater 8, 93–105 (2023). https://doi.org/10.1007/s41127-023-00059-1

For orders please contact us at sales@carbon.org.ua